- Wall-mounted Battery

- Floor Standing Battery

- Stackable Battery

- Rack-mounted Battery

- All-in-one Battery System

- Inverter

Business & Industrial Energy

- 50KW 100KWh

- 100KW 215KWh

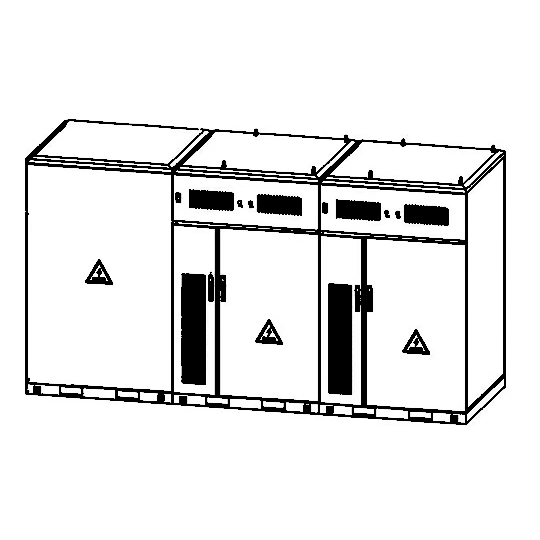

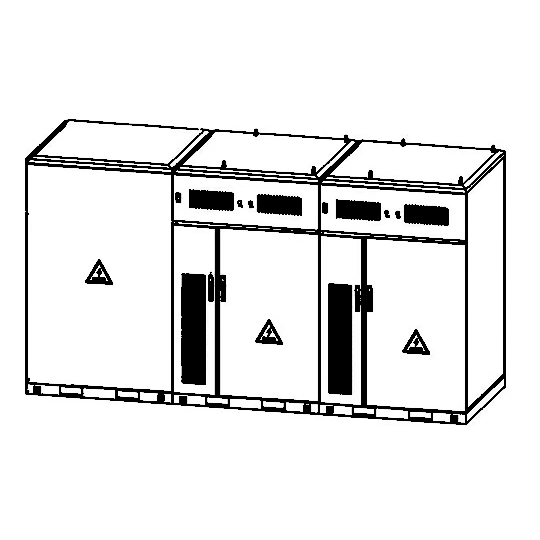

- Customized MW Station

We always plan ahead and get plan B when encountering the shortage of raw materials. First, our purchasing department will prepare raw materials in advance according to the inventory control system.

In addition, except for the main supplier, we select to cooperate with other reliable suppliers if they are verified by our sourcing standards.

.jpg)

We establish multilateral relationship with credible upstream firms, including:

– PCB Manufacturer, who delivers quality PCB based on our design;

– Moulding Factories, which support rapid prototyping of your required molds;

– Battery Co-processing Plant, which ensure adequate amount of high quality lithium batteries

Besides, our own plan and production department makes efficient and well-organized schedule before manufacturing, along with flexible coordination between departments in the process.

We have cooperative warehouses in both the U.S.A and Japan, where our standard products and electric components are stored. This, on the one hand, allows us to achieve faster delivery, and to provide better local after-sales services on the other hand.

We have built solid partnership with several logistics agencies which have 15 years of experience in battery transportation.

They are familiar with customs clearance procedures, and also understand the international logistics rules and regulations for the transportation of batteries.

*We respect your confidentiality and all information are protected.